Flat Rubber Roof Repair Near Me

Flat rubber roof repair near me: This guide explores the essential aspects of maintaining and repairing flat rubber roofs, a common roofing type known for its durability and longevity. We’ll delve into identifying damage, finding reliable contractors, understanding repair methods, and implementing preventative measures to extend the lifespan of your roof. From understanding the different types of rubber roofing materials and common causes of damage to navigating the cost considerations and warranty details, this comprehensive resource empowers you to make informed decisions about your flat rubber roof’s care.

Proper maintenance and timely repairs are crucial for preventing costly and disruptive damage. This guide covers everything from initial assessment and identifying repair needs to selecting a reputable contractor and understanding repair methods and associated costs. By understanding the potential problems and proactive solutions, you can safeguard your investment and ensure the long-term protection of your property.

Understanding Flat Rubber Roofs

Source: pottstownroofing.com

Flat rubber roofs, also known as single-ply membrane roofs, are a popular choice for commercial and residential buildings due to their durability and relatively low cost. Understanding their components, lifespan, and potential problems is crucial for effective maintenance and repair.

Flat Rubber Roof Components

A typical flat rubber roof system comprises several key components working together to provide a waterproof barrier. These include the rubber membrane itself (often EPDM or TPO), a base layer (often insulation), and a protective covering (gravel, pavers, or coatings). Proper installation of each component is critical for long-term performance.

Lifespan of Flat Rubber Roofs

With proper installation and maintenance, a flat rubber roof can last for 20 to 30 years, sometimes even longer. However, factors such as weather exposure, foot traffic, and the quality of installation significantly impact its lifespan. Regular inspections and timely repairs are essential to maximize its longevity.

Types of Rubber Roofing Materials

Several types of rubber roofing materials are available, each with its properties and advantages. Ethylene Propylene Diene Monomer (EPDM) is a common choice known for its durability and flexibility. Thermoplastic Polyolefin (TPO) is another popular option, offering excellent UV resistance and reflectivity. Both materials are relatively easy to repair and maintain.

Causes of Flat Rubber Roof Damage

Various factors can contribute to damage in flat rubber roofs. These include punctures from falling debris, blisters caused by trapped moisture, cracks resulting from temperature fluctuations and UV exposure, and ponding water leading to premature deterioration. Regular inspections can help identify these issues early.

Identifying Repair Needs

A proactive approach to roof maintenance is vital. Regular inspections and prompt attention to signs of damage can prevent costly repairs down the line. In this section Artikels methods for identifying repair needs.

Homeowner’s Flat Rubber Roof Damage Checklist

Homeowners should regularly inspect their roofs for signs of damage. A comprehensive checklist should include checking for punctures, blisters, cracks, ponding water, and any signs of deterioration around seams or flashings. Taking photos and documenting findings is highly recommended.

Comparison of Flat Rubber Roof Damage Types

Source: co.uk

| Damage Type | Appearance | Cause | Severity |

|---|---|---|---|

| Punctures | Small holes or tears in the membrane | Falling debris, sharp objects | Varies, depending on size and location |

| Blisters | Raised, bubble-like areas | Trapped moisture, inadequate ventilation | This can lead to larger problems if left unaddressed |

| Cracks | Linear breaks in the membrane | Temperature fluctuations, UV exposure, aging | Severity depends on the length and depth of cracks |

| Ponding Water | Accumulation of standing water | Poor drainage, clogged drains | Can cause significant damage if not resolved quickly |

Visual Indicators of Needed Repairs

Visible signs of damage, such as punctures, blisters, or cracks, are clear indicators that repair is needed. Discoloration, sagging, or missing sections of the membrane also signal potential problems. Any sign of water leakage inside the building is a critical indicator requiring immediate attention.

Flowchart for Determining Damage Severity

A flowchart can help systematically assess the severity of roof damage. It would typically start with a visual inspection, followed by checks for water penetration, and then categorization of damage as minor, moderate, or severe, guiding the appropriate repair approach.

Finding Local Repair Services

Choosing the right roofing contractor is crucial for a successful repair. Careful consideration of several factors ensures a quality repair and protects your investment.

Questions to Ask Potential Contractors

Before hiring a contractor, ask about their experience with flat rubber roofs, their repair methods, the materials they use, their warranty, and their licensing and insurance. Requesting references and checking online reviews is also recommended.

Verifying Contractor Licenses and Insurance

It is essential to verify that the contractor holds the necessary licenses and insurance. This protects you from potential liabilities in case of accidents or substandard work. Contact your local licensing board to verify credentials.

Factors to Consider When Choosing a Contractor

| Factor | Description | Importance | How to Assess |

|---|---|---|---|

| Price | Total cost of repair | Important, but not the only factor | Obtain multiple quotes |

| Experience | Years of experience in flat rubber roof repair | Essential for quality work | Check references and online reviews |

| Warranty | Guarantee on workmanship and materials | Protects your investment | Review warranty terms carefully |

| Insurance | Liability and workers’ compensation insurance | Protects you from potential liabilities | Verify with the insurance company |

Obtaining Multiple Quotes

Getting quotes from at least three reputable roofing companies allows for comparison and ensures you are getting a fair price. Be sure to provide each contractor with the same information about the damage and the scope of the work.

Repair Methods and Materials

Various repair techniques and materials are used to address different types of flat rubber roof damage. The choice of method and material depends on the extent and nature of the damage.

Repair Techniques for Common Problems

Punctures are often repaired using patches, while blisters may require cutting and resealing. Larger cracks might necessitate seam sealing or more extensive patching. Ponding water necessitates addressing drainage issues and potential membrane damage.

Properties and Applications of Patching Materials

Source: roofingcalc.com

Patching materials, such as EPDM or TPO patches, are chosen to match the existing roof membrane. These materials are designed to be durable, weather-resistant, and compatible with the existing roof system. Adhesives used should be compatible with both the patch and the roof membrane.

Hot-Applied vs. Cold-Applied Repair Methods

Source: co.uk

Hot-applied methods involve using heat to bond the patching material to the roof, while cold-applied methods use adhesives. Hot-applied methods are generally more durable but require specialized equipment and expertise. Cold-applied methods are easier and faster but may not be as durable in extreme conditions.

Preparing a Damaged Area Before Patching

Before applying a patch, the damaged area must be thoroughly cleaned and dried. Any loose or damaged material should be removed. The surface should be primed to ensure proper adhesion of the patch. Following the manufacturer’s instructions for the adhesive is crucial.

Preventative Maintenance

Regular preventative maintenance is key to extending the lifespan of a flat rubber roof. This involves routine inspections, cleaning, and protection from the elements.

Schedule for Routine Inspections

A recommended schedule for routine inspections includes at least two inspections per year, one in spring and one in fall. More frequent inspections might be needed in areas with harsh weather conditions.

Preventative Measures to Extend Roof Life

Source: webflow.com

Regular cleaning to remove debris and leaves prevents ponding water. Addressing any minor damage promptly prevents it from escalating into larger problems. Proper drainage ensures water flows away from the roof.

Cleaning and Maintaining a Flat Rubber Roof

Cleaning should involve removing debris and dirt using a soft brush and water. Avoid using harsh chemicals that could damage the membrane. Regularly check for any signs of damage, and address them promptly.

Protecting the Roof from Extreme Weather

Protecting the roof from extreme weather conditions involves clearing snow and ice buildup to prevent damage. Regularly inspecting for and repairing any damage caused by storms or high winds is essential. Consider using protective coatings to enhance weather resistance.

Cost Considerations

The cost of flat rubber roof repairs varies depending on several factors. Understanding these factors helps in budgeting for repairs.

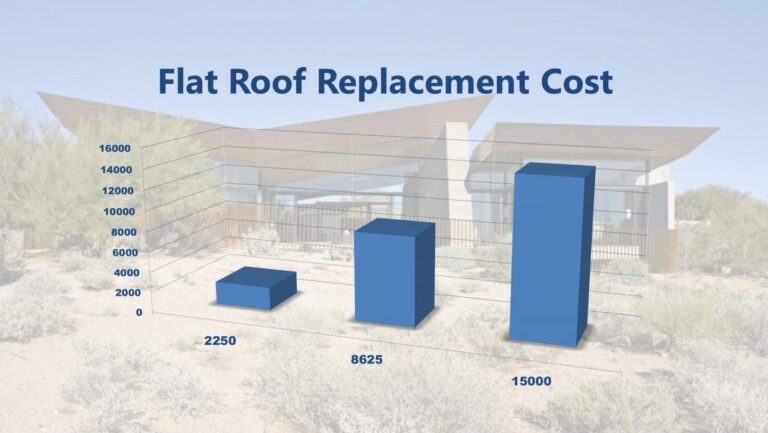

Average Cost of Flat Rubber Roof Repairs

The average cost can range from a few hundred dollars for minor repairs to several thousand dollars for extensive damage. The size of the damaged area, the type of repair needed, and the contractor’s labor rates all influence the overall cost.

Factors Influencing Repair Costs

Factors such as the extent of damage, the type of materials used, the contractor’s labor rates, and the accessibility of the roof all impact the overall cost. Emergency repairs often cost more than scheduled maintenance.

Financing Options for Roof Repairs

Several financing options are available, including home equity loans, personal loans, and financing plans offered by some roofing contractors. It’s advisable to explore all options and choose the one that best suits your financial situation.

Cost Comparison of Different Repair Methods

| Repair Method | Average Cost per Square Foot | Advantages | Disadvantages |

|---|---|---|---|

| Patching | $5-$20 | Cost-effective for minor damage | May not be suitable for extensive damage |

| Seam Sealing | $10-$30 | Effective for sealing cracks and seams | Requires specialized skills and equipment |

| Full Roof Replacement | $5-$15 per square foot | The long-term solution for extensive damage | Most expensive option |

Warranty and Guarantees

Understanding warranty terms and conditions is vital to protect your investment. A comprehensive warranty provides peace of mind.

Typical Warranty Offered for Repairs

Typical warranties for flat rubber roof repairs range from 1 to 10 years, depending on the type of repair and the contractor. The warranty should cover both workmanship and materials.

Understanding Warranty Terms and Conditions

Carefully review the warranty terms and conditions before signing any contract. Understand what is covered, what is not covered, and the process for filing a claim. Keep a copy of the warranty for your records.

Addressing Issues After the Warranty Period

Even after the warranty period, it’s important to maintain your roof properly. If issues arise, contact the contractor to discuss potential solutions. Document all communication and repairs.

Examples of Warranty Clauses, Flat rubber roof repair near me

Warranty clauses should specify the duration of the warranty, what is covered, and the contractor’s responsibilities in case of defects. It should also Articulate the process for filing a claim and resolving disputes.

Safety Precautions: Flat Rubber Roof Repair Near Me

Roof inspections and repairs can be dangerous. Prioritizing safety is paramount.

Safety Measures During Roof Inspection

When inspecting a roof, always use appropriate safety equipment, such as a harness and fall protection system. Avoid working alone, and inform someone of your plans. Inspect the roof only in good weather conditions.

Safety Procedures During Repair Work

Follow all safety guidelines provided by the manufacturer of repair materials and equipment. Use appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hard hats. Secure tools and materials to prevent falls.

Necessary Safety Equipment

Essential safety equipment includes a harness, fall protection system, safety glasses, gloves, hard hats, and sturdy footwear. Ensure all equipment is in good working condition before use.

Following Local Building Codes and Regulations

Source: co.uk

Always comply with all local building codes and regulations when conducting roof inspections and repairs. This ensures the safety and structural integrity of the building and avoids potential legal issues.

FAQ Corner

What is the average lifespan of a flat rubber roof?

The average lifespan of a flat rubber roof is typically 15-20 years, but this can vary depending on factors like weather conditions, maintenance, and the quality of materials used.

How often should I inspect my flat rubber roof?

Regular inspections, ideally twice a year (spring and fall), are recommended to catch minor issues before they become major problems. Pay close attention after severe weather events.

What are some signs of a failing flat rubber roof?

Signs include blisters, cracks, punctures, ponding water, and visible deterioration of the roofing membrane. Leaks inside the building are a clear indication of a serious problem.

Can I repair my flat rubber roof myself?

Minor repairs like patching small punctures may be manageable for DIY enthusiasts with the right materials and skills. However, significant repairs are best left to experienced roofing professionals for safety and quality.

What should I look for when choosing a roofing contractor?

Look for licensed and insured contractors with proven experience in flat rubber roof repairs. Check online reviews, request references, and obtain multiple quotes before making a decision.