How Much Is It To Install Insulation

How much is it to install insulation? This seemingly simple question opens a door to a surprisingly complex world of factors influencing the final cost. From the type of insulation chosen – fiberglass, spray foam, or cellulose – to the size of the area needing treatment and the accessibility of that space, numerous variables impact the overall expense. Understanding these factors empowers homeowners to make informed decisions and budget effectively for this crucial home improvement project.

This guide delves into the specifics, providing a comprehensive overview of the costs associated with insulation installation. We’ll explore the various types of insulation available, their respective costs, and the labor implications involved. We will also address regional variations in pricing, compare DIY versus professional installation, and help you navigate the process of selecting a qualified contractor. By the end, you’ll have a clearer understanding of what to expect and how to best approach your insulation project.

Factors Affecting Insulation Installation Cost

Several key factors significantly influence the overall cost of insulation installation. Understanding these factors allows homeowners to make informed decisions and budget effectively for their projects. This section will explore the impact of insulation type, area size, accessibility, and the breakdown of material versus labor costs.

Insulation Type and Cost

Source: com.au

The type of insulation chosen significantly impacts the project’s cost. Fiberglass batts, a common and relatively inexpensive option, are suitable for attics and walls. Spray foam insulation, while more expensive upfront, offers superior air sealing and R-value, leading to potential long-term energy savings. Cellulose insulation, made from recycled paper, provides good insulation properties at a moderate cost. The choice depends on the specific needs and budget of the homeowner.

Square Footage and Insulation Cost

The total square footage of the area requiring insulation directly correlates with the overall cost. Larger areas naturally require more materials and labor, leading to higher expenses. Accurate measurement of the area to be insulated is crucial for obtaining precise cost estimates.

Accessibility and Labor Costs

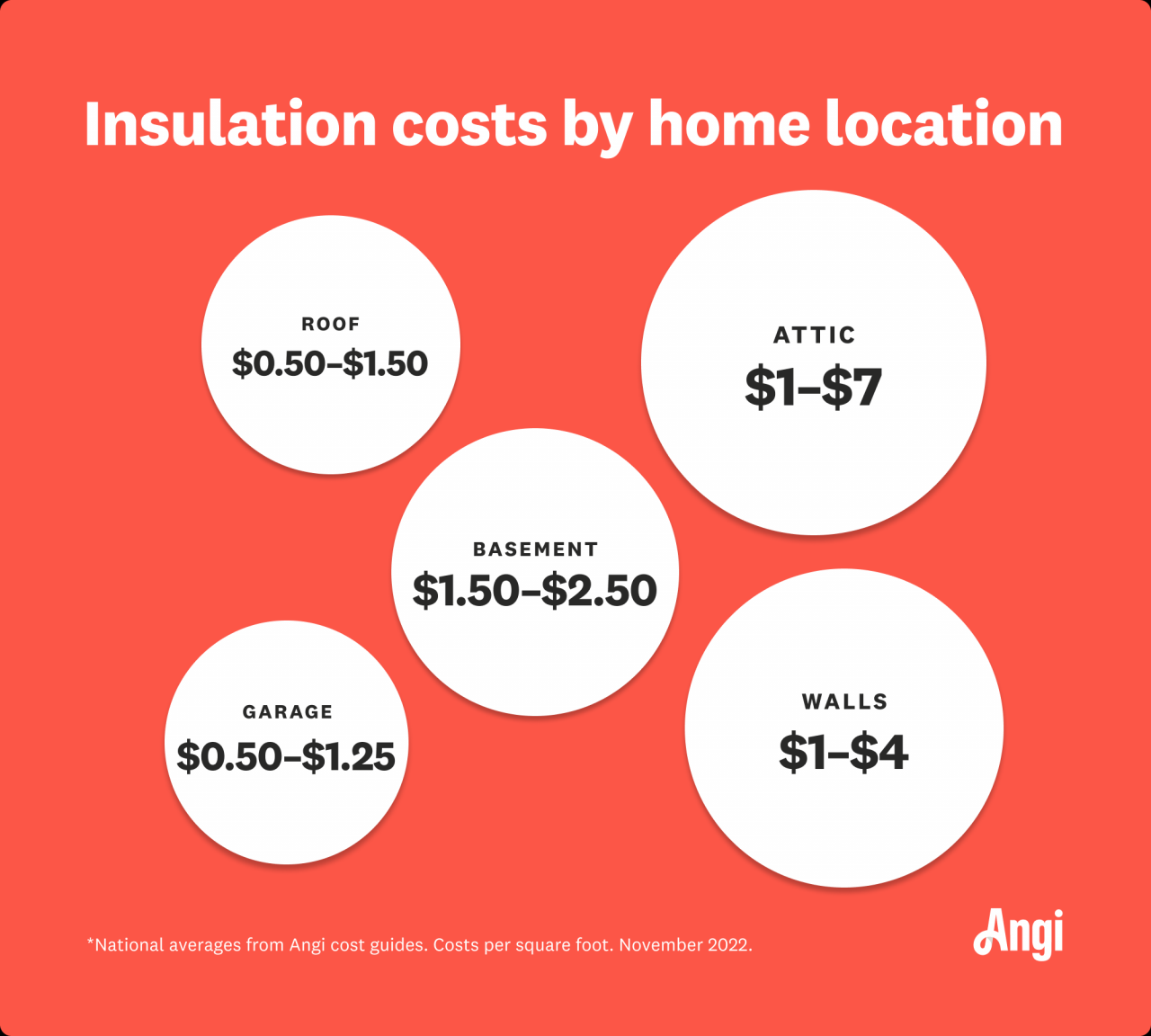

Accessibility of the area to be insulated greatly affects labor costs. Insulating an easily accessible attic is less labor-intensive than insulating walls or a crawl space, which may require specialized equipment and techniques. Difficult-to-reach areas translate to higher labor charges.

Material vs. Labor Costs

The total cost of insulation installation is a combination of material and labor costs. Material costs depend on the type and quantity of insulation used, while labor costs are influenced by factors such as accessibility, the complexity of the project, and the contractor’s hourly rate. A typical breakdown might see materials accounting for 40-60% of the total cost, with labor making up the remainder.

Cost Comparison Table for Insulation Types

| Insulation Type | Cost per Square Foot (Low) | Cost per Square Foot (Average) | Cost per Square Foot (High) |

|---|---|---|---|

| Fiberglass Batts | $0.30 | $0.75 | $1.20 |

| Cellulose | $0.50 | $1.00 | $1.50 |

| Spray Foam | $1.50 | $3.00 | $4.50 |

Labor Costs and Contractor Selection

Selecting the right insulation contractor is crucial for a successful and cost-effective project. This section details factors to consider when choosing a contractor, typical labor rates, and potential hidden costs.

Contractor Selection Criteria

Source: com.au

When choosing an insulation contractor, several key factors should be considered: experience in similar projects, proper licensing and insurance, positive customer reviews and references, and a clear, detailed quote outlining all costs. Verifying these aspects ensures a professional and reliable service.

Labor Rates for Insulation Installers

Typical hourly or daily rates for insulation installers vary depending on location, experience, and the complexity of the project. Expect rates to range from $50 to $100 per hour or $300 to $600 per day, although these are broad estimates and can fluctuate significantly.

Contractor Size and Cost

The cost difference between hiring a single contractor versus a larger company can be minimal or substantial, depending on the project size and scope. Smaller contractors may offer more personalized service, while larger companies might provide more competitive pricing for larger jobs. Choosing between them requires careful evaluation of individual needs and priorities.

Hidden Costs in Insulation Installation

Potential hidden costs associated with insulation installation include permits (required in some jurisdictions), material disposal fees, and unexpected structural repairs discovered during the installation process. It’s crucial to get a comprehensive quote that includes all potential expenses to avoid surprises.

Contractor Selection Checklist

- Verify licensing and insurance

- Check online reviews and references

- Obtain at least three detailed quotes

- Clarify payment terms and schedules

- Confirm warranty information

- Ask about cleanup procedures

Types of Insulation and Their Costs: How Much Is It To Install Insulation

Various insulation materials offer different levels of thermal performance and installation costs. Understanding their characteristics is crucial for making an informed choice. This section provides detailed descriptions, cost comparisons, and installation method details.

Fiberglass Batts

Fiberglass batts are a common, relatively inexpensive option, easy to install in wall cavities and attics. They offer decent R-values but may not provide as airtight a seal as other options.

Blown-in Cellulose

Cellulose insulation, made from recycled paper, is blown into walls and attics, filling irregular spaces effectively. It offers good thermal performance at a moderate cost and is environmentally friendly.

Spray Foam Insulation

Source: neeeco.com

Spray foam insulation expands to fill cavities, providing excellent air sealing and high R-values. It’s more expensive than other options but offers superior energy efficiency and can improve indoor air quality.

Rigid Foam Boards, How much is it to install insulation

Rigid foam boards, such as XPS and polyisocyanurate, are used for exterior wall insulation and roofing. They offer high R-values and are durable, but installation can be more complex and expensive.

R-Value and Thermal Performance Comparison

R-value indicates the insulation’s resistance to heat flow. Higher R-values mean better insulation. Spray foam generally boasts the highest R-value per inch, followed by rigid foam boards, then cellulose, and finally fiberglass batts.

Cost-Effectiveness and Long-Term Value

Source: ecosprayinsulation.ca

While spray foam has a higher initial cost, its superior energy efficiency can lead to significant long-term savings on energy bills. Cellulose offers a good balance between cost and performance. Fiberglass batts are the most budget-friendly option but may require more frequent replacement.

Insulation Installation Methods and Costs

Installation methods vary by insulation type. Fiberglass batts are relatively easy to install, while spray foam requires specialized equipment and trained professionals. The complexity of installation directly impacts the overall cost.

Pros and Cons of Each Insulation Type

Each insulation type has its advantages and disadvantages concerning cost and effectiveness. This table summarizes those considerations:

| Insulation Type | Pros | Cons |

|---|---|---|

| Fiberglass Batts | Inexpensive, easy to install | A lower R-value, may not seal air gaps effectively |

| Cellulose | Good R-value, environmentally friendly, fills irregular spaces well | Can be messy to install |

| Spray Foam | High R-value, excellent air seal, improves air quality | Expensive, requires specialized equipment and professionals |

| Rigid Foam Boards | High R-value, durable, good for exterior applications | Can be difficult to install, expensive |

Regional Variations in Insulation Costs

The cost of insulation installation varies significantly across different geographic regions due to several factors. This section examines these factors and provides a general overview of regional cost differences.

Factors Contributing to Regional Differences

Several factors contribute to regional variations in insulation installation costs. These include differences in labor rates, material availability, transportation costs, local building codes and climate conditions influencing insulation requirements, and the prevalence of specific insulation types in a region.

Regional Cost Comparisons

Generally, areas with higher labor costs and limited access to materials tend to have higher insulation installation prices. For example, coastal regions might have higher costs due to transportation expenses. Areas with stricter building codes mandating higher R-values will also see increased costs.

Climate and Building Codes Influence

Source: angi.com

Climate significantly impacts insulation requirements. Colder climates necessitate higher R-values, leading to increased material and labor costs. Building codes often specify minimum insulation levels, further influencing overall expenses.

Impact of Local Regulations

Local regulations, such as permit requirements and disposal fees for certain insulation materials, can add to the overall installation cost. These regulations can vary significantly between states or even municipalities.

Illustrative Map of Cost Variations

A hypothetical map of the United States illustrating insulation cost variations would show higher costs in the Northeast and Northwest regions, reflecting higher labor rates and stricter building codes. The Southeast and Southwest regions might exhibit lower costs due to generally milder climates and lower labor rates. However, specific costs would vary significantly based on local factors and project specifics.

DIY vs. Professional Insulation Installation

Homeowners often consider whether to install insulation themselves or hire a professional. This section compares the costs and risks associated with each approach.

DIY vs. Professional Cost Comparison

DIY insulation installation can seem cost-effective initially, but potential mistakes can lead to higher costs in the long run. Professional installers possess expertise, in ensuring proper installation and avoiding costly errors. While professional installation is more expensive upfront, it minimizes risks and ensures optimal performance.

DIY Insulation: Tools and Materials

DIY insulation installation requires specific tools and materials, including safety equipment (respirator, gloves, eye protection), measuring tools, cutting tools (for batts), and the insulation material itself. The cost of these tools and materials adds to the overall DIY expense.

Potential Risks of DIY Installation

Attempting DIY insulation installation carries risks, including improper installation leading to reduced energy efficiency, health hazards from inhaling insulation particles, and potential structural damage. These risks can negate any initial cost savings.

Long-Term Cost Savings

Source: com.au

Professional installation, while more expensive initially, often leads to better long-term energy savings due to optimal insulation performance. Improper DIY installation can result in higher energy bills and necessitate costly repairs down the line.

Cost Comparison Table: DIY vs. Professional

| Item | DIY Cost | Professional Cost | Risk Level |

|---|---|---|---|

| Materials | Variable, depending on insulation type and quantity | Included in the professional quote | Low |

| Labor | Your time (value varies) | Variable, depending on contractor and project size | Medium |

| Potential Risks | High (health, structural damage, inefficient installation) | Low (with reputable contractor) | High |

Essential Questionnaire

What is the average lifespan of different insulation types?

The lifespan varies depending on the type. Fiberglass batts typically last 50-75 years, while spray foam can last 50+ years. Cellulose insulation generally lasts 50-100 years.

Can I finance insulation installation?

Yes, many contractors offer financing options, and some home improvement loans specifically cover energy efficiency upgrades. Check with your contractor or a financial institution for available options.

Are there any tax credits or rebates available for insulation installation?

Yes, many local and federal government programs offer tax credits or rebates for energy-efficient home improvements, including insulation. Check with your local energy provider or government websites for current offerings.

How long does the insulation installation process typically take?

The duration varies greatly depending on the size of the area, type of insulation, and accessibility. Smaller projects might take a day, while larger ones could take several days or even weeks.

What should I do if I discover mold or other damage during the insulation installation?

Immediately stop the work and contact a qualified professional to assess and remediate the mold or damage before proceeding with insulation installation. Ignoring this could lead to further issues and increased costs.