Best Rigid Insulation For Roof

The best rigid insulation for roof selection is crucial for energy efficiency and long-term building performance. This guide delves into the various types of rigid insulation, including expanded polystyrene (EPS), extruded polystyrene (XPS), polyurethane (polyiso), and fiberglass, examining their thermal properties, installation methods, and cost-effectiveness. We’ll explore how factors like climate, moisture resistance, and fire safety influence material choice, providing a comprehensive overview to assist in making informed decisions for your roofing project.

Understanding the nuances of each insulation type, from their manufacturing processes to their long-term durability, is key to maximizing energy savings and minimizing environmental impact. This guide will equip you with the knowledge to choose the best rigid insulation for your specific needs, considering both initial costs and the long-term return on investment (ROI).

Types of Rigid Roof Insulation

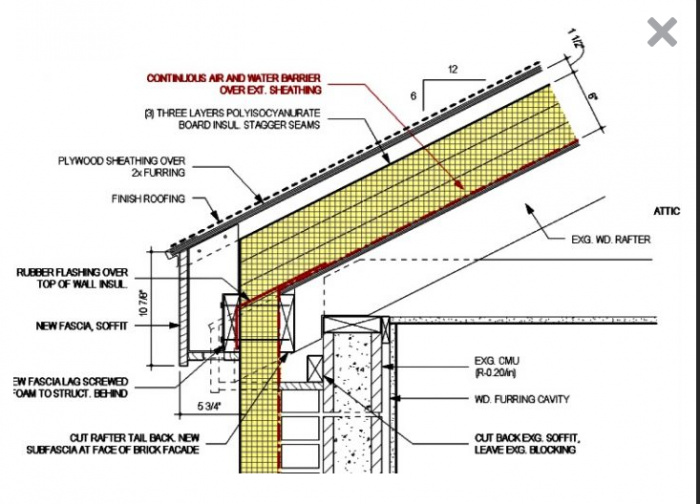

Source: artisanins.com

Choosing the right rigid roof insulation is crucial for energy efficiency and building longevity. Several materials offer distinct properties and performance characteristics. Understanding these differences is key to making an informed decision.

Expanded Polystyrene (EPS)

EPS is a lightweight, closed-cell foam created by injecting expanding agents into polystyrene beads. The beads are then molded into rigid boards. Its closed-cell structure provides excellent thermal resistance and moisture resistance, making it suitable for various climates. However, its compressive strength is relatively lower compared to other rigid insulation options.

Extruded Polystyrene (XPS)

XPS, also a closed-cell foam, is manufactured through a continuous extrusion process. This results in a denser, more rigid board with higher compressive strength than EPS. Its superior resistance to moisture makes it a popular choice for applications where ground contact or high moisture levels are expected, such as below-grade applications or in high-humidity climates. It also boasts a higher R-value per inch than EPS.

Polyurethane (Polyiso)

Source: greenbuildingadvisor.com

Polyiso foam is manufactured by expanding a mixture of isocyanate and polyol. This process creates a rigid foam with a high R-value and good thermal performance. Often faced with aluminum foil or other reflective materials to enhance its reflective properties and reduce radiant heat transfer. Polyiso is known for its excellent thermal performance but can be more susceptible to moisture damage if not properly installed and protected.

Fiberglass is the best rigid insulation for roofs.

Fiberglass insulation, though not strictly “foam” insulation, is often used in rigid board form for roofing applications. Manufactured by melting glass and spinning it into fine fibers, which are then bonded together with a resin binder to create rigid panels. Fiberglass boards offer good thermal performance but are less moisture-resistant than foam insulation types. It’s also less dense and less resistant to compression.

Thermal Performance Comparison

| Material | R-value per inch | Density (lbs/ft³) | Cost (USD/board ft) |

|---|---|---|---|

| EPS | 3.7-4.0 | 1.5 – 2.0 | $0.30 – $0.60 |

| XPS | 5.0-7.0 | 1.8 – 2.5 | $0.50 – $1.00 |

| Polyiso | 6.0-8.0 | 2.0 – 2.5 | $0.70 – $1.50 |

| Fiberglass | 3.0-4.5 | 1.0 – 1.5 | $0.40 – $0.80 |

Note: R-values and costs are approximate and can vary based on manufacturer, thickness, and region.

Factors Affecting Insulation Choice

Selecting the optimal rigid roof insulation involves considering several factors beyond just the R-value. Climate, moisture resistance, fire safety, and installation ease all play significant roles.

Climate Impact

Extreme temperatures and high humidity significantly influence insulation performance. In hot, humid climates, moisture resistance is paramount to prevent mold and mildew growth. Closed-cell foams like XPS are well-suited for these conditions. In colder climates, a higher R-value is crucial to minimize heat loss. Materials like polyiso or high-density XPS might be preferred.

Other Crucial Factors

Beyond the R-value, moisture resistance is critical for preventing damage to the roof structure and insulation itself. Fire resistance, as defined by building codes, is another essential factor, especially for areas with strict fire safety regulations. Ease of installation and the cost of labor should also be considered. Materials that are easier to cut, handle, and install can reduce labor costs.

Long-Term Durability

The long-term performance of rigid insulation varies based on material and environmental exposure. UV degradation can affect some materials over time, requiring the use of protective coatings. Proper installation and protection from moisture are crucial to maximize the lifespan of any rigid insulation system.

Installation Methods and Best Practices

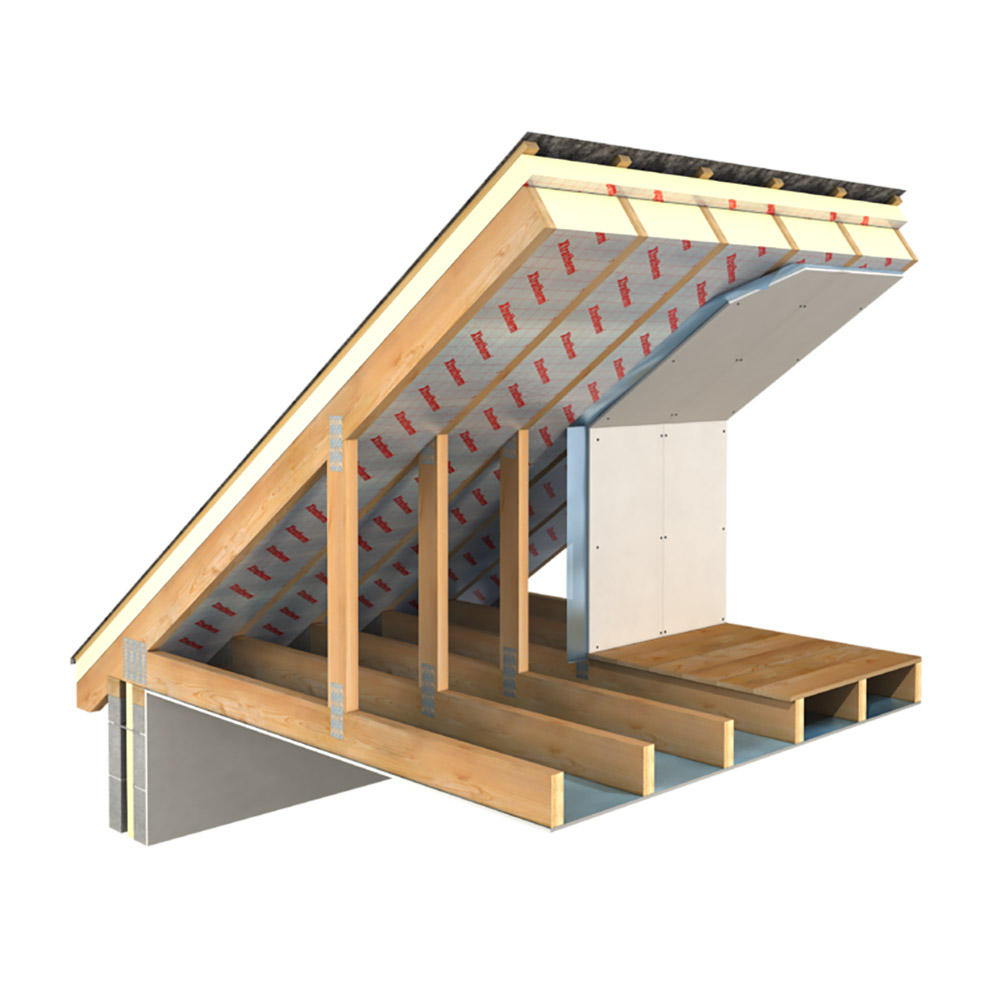

Source: unitedthermalsystems.com

Proper installation of rigid foam insulation is essential for maximizing its thermal performance and longevity. This section details best practices for sloped roofs.

Step-by-Step Installation on a Sloped Roof

- Prepare the Roof Deck: Ensure the roof deck is clean, dry, and free of debris. Address any structural issues or damage.

- Install Vapor Barrier: Apply a continuous vapor barrier to prevent moisture from entering the insulation cavity. Overlap seams and seal thoroughly.

- Install Insulation: Cut and fit rigid foam boards to the roof’s contours. Ensure tight fits between boards to minimize thermal bridging.

- Fastening: Secure the insulation boards using appropriate fasteners, ensuring proper spacing to avoid puncturing the vapor barrier.

- Sealing: Seal all joints and gaps between insulation boards with a compatible sealant to prevent air infiltration.

- Install Roofing Material: Install the chosen roofing material over the insulation layer.

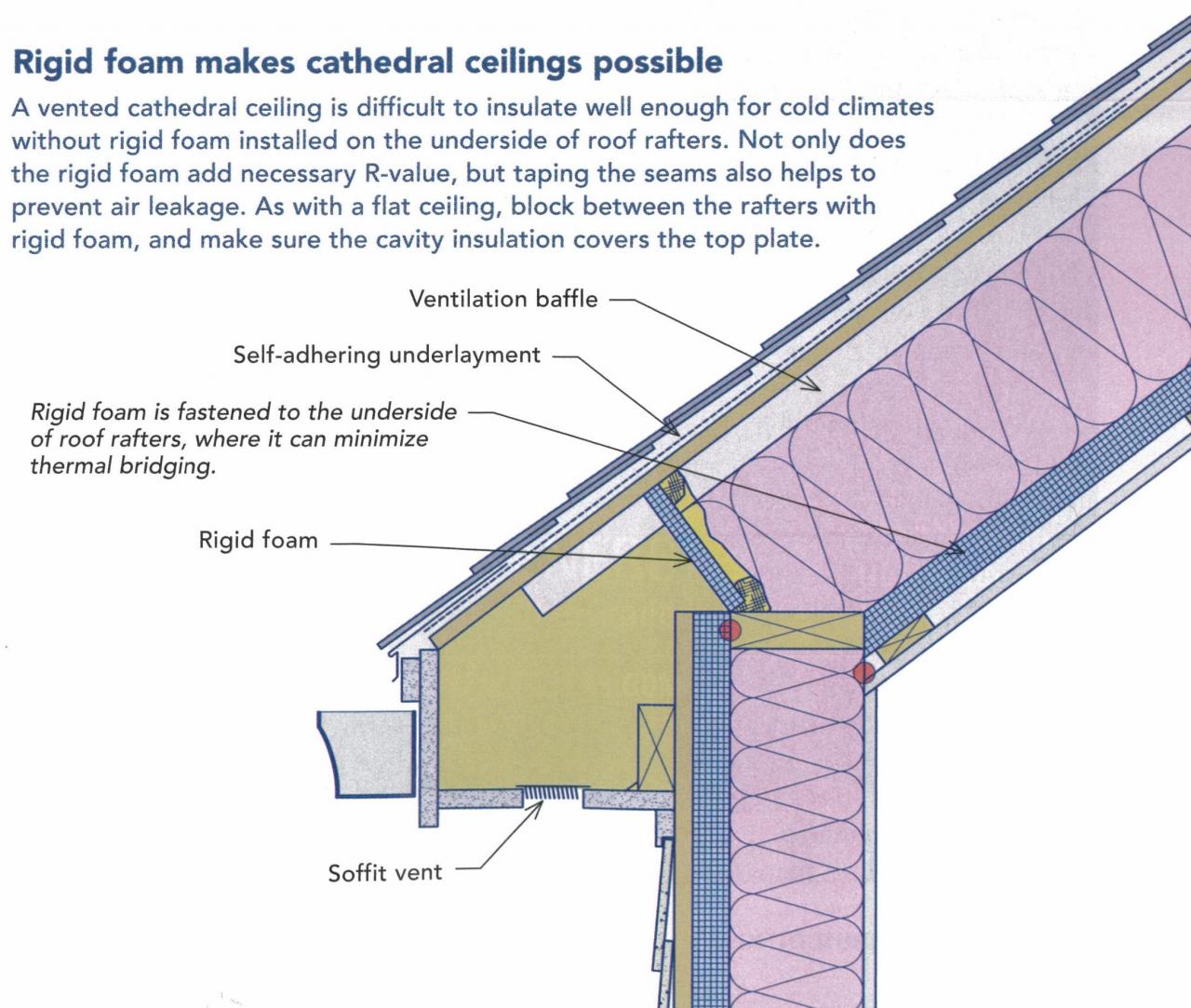

Ventilation

Source: pinimg.com

Proper ventilation is crucial for preventing moisture buildup within the roof assembly. A well-ventilated roof system includes soffit vents at the lower edge of the roof, ridge vents at the peak, and adequate air space between the insulation and roofing material.

Minimizing Thermal Bridging

Thermal bridging occurs when heat flows through conductive pathways, such as fasteners or gaps in the insulation. Minimizing thermal bridging requires careful attention to detail during installation. Using staggered joints, filling gaps with sealant, and selecting insulation with high thermal resistance can help reduce thermal bridging.

Cost Considerations and ROI

Source: co.uk

While the initial cost of high-performance rigid insulation might be higher, the long-term energy savings can significantly offset the upfront investment.

Initial Costs

Initial costs vary significantly depending on material selection, labor costs, and the complexity of the installation. Higher R-value materials typically have higher initial costs but offer greater long-term energy savings.

Long-Term Cost Savings

| Insulation R-value | Annual Energy Savings (USD) | Payback Period (Years) |

|---|---|---|

| R-15 | $150 | 5 |

| R-20 | $250 | 3 |

| R-30 | $400 | 2 |

Note: Annual energy savings and payback periods are estimates and vary based on factors like climate, energy prices, and building size.

Return on Investment (ROI)

Improving roof insulation can lead to a substantial ROI through reduced energy bills and increased property value. A well-insulated home is more energy-efficient, comfortable, and attractive to potential buyers, resulting in a higher resale value.

Environmental Impact and Sustainability

The environmental impact of rigid insulation varies depending on the material and manufacturing process. Sustainable choices should consider both the carbon footprint and end-of-life options.

Manufacturing Impact

The manufacturing process of each insulation type has different environmental consequences. Some materials have higher embodied carbon than others, and the use of recycled content can significantly reduce the environmental impact. Polyiso and EPS, for example, can have significant embodied carbon compared to other options.

Recyclability and End-of-Life

Recyclability varies considerably among insulation types. Some manufacturers offer recycling programs for their products, while others may not be easily recyclable. Proper disposal of insulation materials is important to minimize environmental impact.

Sustainable Practices

Choosing insulation with recycled content, using efficient installation techniques to minimize waste, and selecting materials with lower embodied carbon are all key aspects of sustainable rigid roof insulation practices.

Code Compliance and Safety: Best Rigid Insulation For Roof

Adhering to building codes and safety regulations is crucial for a safe and effective roof insulation installation. Fire safety standards are particularly important.

Building Codes and Regulations

Building codes specify minimum R-values for roof insulation, depending on the climate zone. These codes also address fire safety requirements, including the use of fire-resistant materials and proper installation techniques.

Appropriate Insulation Ratings

Using appropriately rated insulation is essential to meet code requirements and ensure the building’s thermal performance and fire safety. Incorrectly rated insulation can lead to code violations and compromise the building’s safety and energy efficiency.

Safety Precautions

Safety precautions during the installation and handling of rigid roof insulation include wearing appropriate personal protective equipment (PPE), such as gloves, eye protection, and respiratory protection. Following the manufacturer’s instructions for handling and installation is also critical.

Case Studies: Successful Rigid Roof Insulation Projects

A hypothetical case study illustrates the benefits of rigid foam insulation. Consider a single-family home in a hot, arid climate with a sloped asphalt shingle roof.

Hypothetical Case Study

The existing roof had R-13 fiberglass batts. Replacing them with R-20 polyiso foam reduced energy consumption for cooling by 30%, resulting in an annual energy savings of approximately $350. The initial cost of the insulation and installation was $2,500. The payback period for this investment is less than 7 years. The homeowner also noted a significant improvement in indoor comfort, with less temperature fluctuation.

Visual Representation

Imagine a cross-section of the roof. The existing R-13 fiberglass batts are light beige, loosely packed between rafters. The new R-20 polyiso boards are a darker grey, neatly fitted between the rafters, creating a uniform, dense layer. The reflective aluminum foil facing of the polyiso is visible. The top layer shows the dark grey asphalt shingles. The contrast between the loose fiberglass and the tightly fitted polyiso clearly illustrates the improvement in thermal performance and air sealing.

General Inquiries

What is the difference between EPS and XPS insulation?

EPS (expanded polystyrene) is less dense and less expensive than XPS (extruded polystyrene), but XPS offers superior moisture resistance and higher R-values per inch.

How long does rigid roof insulation typically last?

With proper installation, most rigid insulation materials can last for 20-30 years or more, depending on the material and environmental conditions.

Can I install rigid insulation myself?

While DIY installation is possible for some, complex roof designs or large projects often require professional expertise for optimal results and safety.

Are there any government incentives for installing better roof insulation?

Many governments offer tax credits or rebates for energy-efficient home improvements, including roof insulation upgrades. Check with your local and national energy agencies for current programs.

What is the best way to deal with thermal bridging in my roof?

Minimize thermal bridging by using continuous insulation, staggering joints, and ensuring proper sealing around penetrations and fasteners.