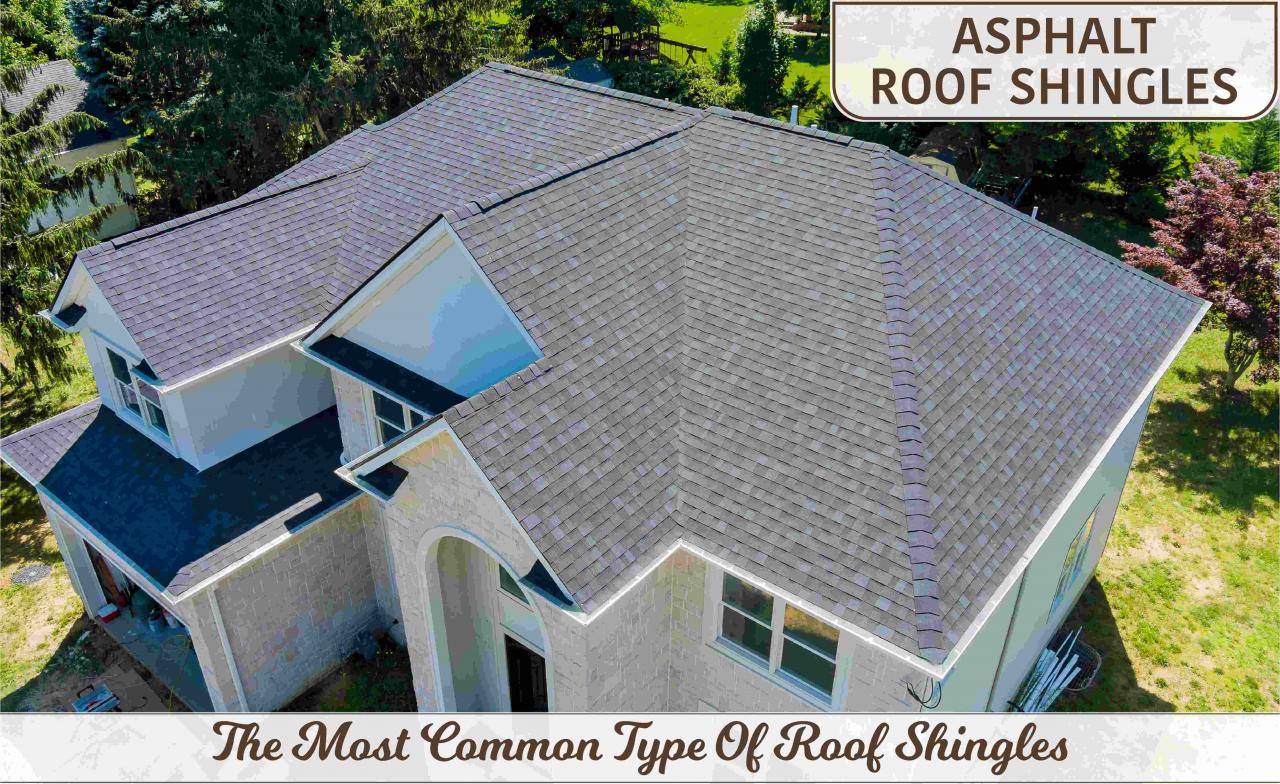

Asphalt Shingle Tiles

Asphalt shingle tiles represent a popular and versatile roofing solution, offering a balance of affordability, durability, and aesthetic appeal. This guide delves into the multifaceted world of asphalt shingles, exploring their manufacturing processes, diverse styles, installation techniques, environmental impact, and long-term cost considerations. From understanding the raw materials and construction methods to mastering installation best practices and addressing common maintenance concerns, we aim to provide a comprehensive overview for homeowners, contractors, and anyone interested in learning more about this ubiquitous roofing material.

We will examine the various types of asphalt shingles available, highlighting their unique properties and performance characteristics. We’ll also discuss the importance of proper installation and maintenance to ensure the longevity and effectiveness of your asphalt shingle roof. Finally, we will address the environmental considerations associated with asphalt shingle production and disposal, exploring sustainable alternatives and practices within the industry.

Asphalt Shingle Tile Manufacturing

Asphalt shingles, a prevalent roofing material, undergo a multifaceted manufacturing process involving several key stages. Understanding this process reveals the material properties and ultimately, the performance characteristics of the final product. This section details the production of asphalt shingles, from raw material sourcing to finished product packaging, encompassing the roles of different asphalt types, reinforcing materials, and the application of mineral granules.

Asphalt Shingle Production Stages

The manufacturing of asphalt shingles is a complex process that involves several distinct stages, each contributing to the final product’s quality and performance. This process ensures a durable and weather-resistant roofing solution.

| Stage | Materials | Process Description | Quality Control Checks |

|---|---|---|---|

| Fiberglass Mat Production | Glass fibers, binders | Continuous filaments of glass are spun and bonded together to form a strong, flexible mat. | Thickness, strength, and uniformity are checked. |

| Asphalt Saturation | Fiberglass mat, asphalt (oxidized or SBS modified) | The fiberglass mat is saturated with hot asphalt to provide waterproofing and structural integrity. The type of asphalt influences the shingle’s flexibility, durability, and temperature resistance. | Uniform saturation and asphalt penetration are assessed. |

| Mineral Granule Application | Saturated mat, mineral granules (limestone, slate, etc.) | Mineral granules are applied to the asphalt surface to provide UV protection, color, and fire resistance. This is typically done using a rotating drum. | Granule adhesion, coverage, and color consistency are verified. |

| Cutting and Shaping | Granulated shingles | The saturated and granulated asphalt mat is cut into individual shingle shapes (e.g., 3-tab, architectural) using precision cutting machines. | Dimensional accuracy and shape consistency are checked. |

| Packaging | Finished shingles | Shingles are carefully bundled and packaged for transport and installation. | Packaging integrity and shingle protection are ensured. |

Types of Asphalt and Their Impact

The type of asphalt used significantly influences the shingle’s properties. Oxidized asphalt is more economical but less flexible and durable compared to Styrene-Butadiene-Styrene (SBS) modified asphalt, which offers superior flexibility, durability, and weather resistance, especially in extreme temperatures.

Role of Reinforcing Materials

Fiberglass mats are the primary reinforcing material, providing structural integrity and preventing the shingle from tearing or becoming brittle. Other reinforcing materials, though less common, might include organic felt or other composite materials, each influencing the overall shingle strength and flexibility.

Mineral Granule Application Process

The application of mineral granules is a crucial step. The saturated asphalt mat passes through a rotating drum containing the granules. The heat and adhesive properties of the asphalt ensure the granules adhere securely to the surface. The type and color of granules determine the shingle’s aesthetic appeal and UV resistance.

Types and Styles of Asphalt Shingles

Source: gharpedia.com

Asphalt shingles are categorized into different types based on their construction and aesthetic features. Each type offers a unique balance of performance characteristics, influencing its suitability for specific climates and architectural styles.

Asphalt Shingle Categorization

Three main categories exist: 3-tab, architectural, and laminated shingles. 3-tab shingles are the most economical, featuring a simple three-tab design. Architectural shingles, also known as dimensional shingles, have a more textured, layered appearance, offering enhanced durability and aesthetic appeal. Laminated shingles, a type of architectural shingle, consist of multiple layers bonded together for increased thickness and longevity.

Aesthetic and Performance Comparisons

Aesthetically, 3-tab shingles offer a simpler, flatter profile, while architectural and laminated shingles provide more dimensional depth and texture, mimicking the look of wood shakes or slate. Performance-wise, architectural and laminated shingles generally offer superior wind resistance, fire resistance, and a longer lifespan compared to 3-tab shingles. Color and texture options vary widely across all types.

Shingle Cross-Sections, Asphalt shingle tiles

3-Tab Shingle: Imagine a relatively flat, thin shingle with three distinct tabs, each slightly overlapping the next. The core is a single layer of saturated fiberglass mat.

Architectural Shingle: Picture a thicker shingle with multiple layers of asphalt and fiberglass, creating a more textured, dimensional surface. The layers are often staggered or layered to create depth and shadow.

Asphalt Shingle Installation and Maintenance

Proper installation and regular maintenance are crucial for maximizing the lifespan and performance of an asphalt shingle roof. This section Articulates the key steps in installation, best practices for underlayment, and a recommended maintenance schedule.

Asphalt Shingle Installation Guide

- Preparation: Ensure the roof deck is clean, dry, and free of debris. Inspect for any damaged wood.

- Underlayment Installation: Apply a suitable underlayment (e.g., felt, synthetic) according to manufacturer instructions. This provides an additional layer of waterproofing.

- Starter Course: Install a starter course of shingles along the eaves to provide a neat and secure base for the remaining shingles.

- Shingle Installation: Begin installing shingles, ensuring proper alignment and overlap according to manufacturer specifications. Nail securely at the designated points.

- Ridge and Hip Installation: Install ridge and hip caps to complete the roof, ensuring proper sealing and weather protection.

- Cleanup: Remove all debris and dispose of it properly.

Underlayment Selection and Application

Source: amazonaws.com

Choosing the right underlayment is crucial for waterproofing. Synthetic underlayments offer superior water resistance and durability compared to traditional felt underlayments. Proper application involves overlapping layers and securing them to the roof deck with nails or staples.

Common Installation Issues and Solutions

- Improper Nail Placement: Use the correct nail length and placement to ensure secure fastening. Loose nails can lead to shingle blow-off.

- Insufficient Overlap: Ensure proper shingle overlap to prevent water penetration. Insufficient overlap can cause leaks.

- Uneven Roof Deck: An uneven roof deck can lead to improper shingle alignment and potential leaks. Address any significant unevenness before installation.

Regular Maintenance Schedule

- Annual Inspection: Check for missing, damaged, or loose shingles, and address any issues promptly.

- Cleaning: Remove leaves, debris, and moss from the roof surface to prevent damage and water retention.

- Gutter Cleaning: Clean gutters regularly to prevent water damage to the roof and foundation.

- Repairing Damaged Areas: Repair any damaged areas promptly to prevent further damage and water penetration.

Environmental Impact and Sustainability

The environmental impact of asphalt shingles is a complex issue encompassing production, use, and disposal. However, advancements in manufacturing and recycling are improving the sustainability of this roofing material.

Environmental Impacts

Production involves energy consumption and greenhouse gas emissions. Disposal of asphalt shingles can contribute to landfill waste. The extraction of raw materials also has environmental consequences.

Role of Recycled Materials

Recycled materials, such as recycled asphalt and fiberglass, are increasingly incorporated into asphalt shingle manufacturing, reducing reliance on virgin materials and minimizing the environmental footprint.

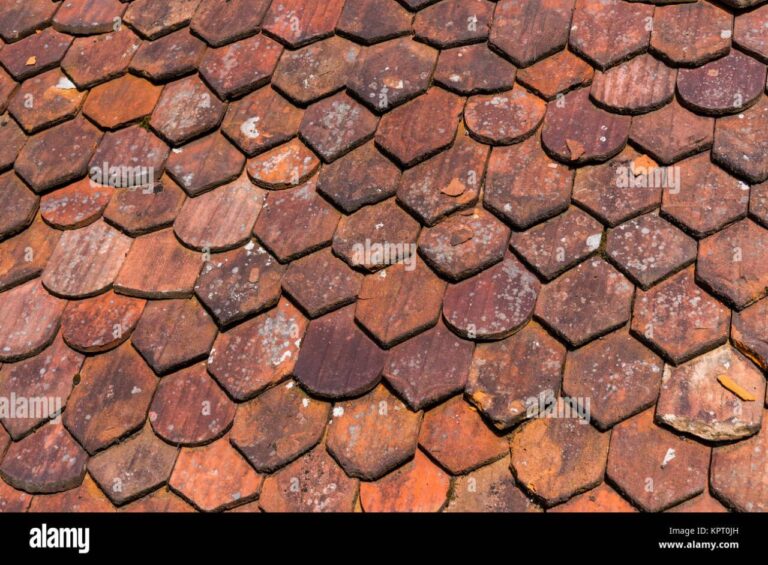

Comparison with Other Roofing Materials

Source: roofingbylandmark.com

Compared to other roofing materials like clay tiles or metal roofing, asphalt shingles generally have a lower initial cost but may have a shorter lifespan and require more frequent replacement. The environmental impact varies depending on the manufacturing process and material sourcing of each material type.

Sustainable Manufacturing Practices

Source: classicroofreplacement.com

Manufacturers are adopting various sustainable practices, including using recycled materials, reducing energy consumption in production, and developing more environmentally friendly asphalt formulations.

Cost and Lifespan Considerations

The cost and lifespan of asphalt shingles are influenced by several factors, including material quality, shingle style, and installation costs. This section provides a comparative analysis of cost-effectiveness.

Factors Influencing Cost

Material quality (e.g., type of asphalt, mineral granules), shingle style (e.g., 3-tab vs. architectural), installation costs (labor, permits), and regional variations in material prices all impact the overall cost.

Lifespan Under Various Climates

The lifespan of asphalt shingles varies based on climate and shingle type. In moderate climates, 3-tab shingles might last 15-20 years, while architectural shingles could last 25-30 years. Harsh climates with extreme temperatures or heavy snowfall can shorten the lifespan significantly.

Long-Term Cost-Effectiveness

While asphalt shingles may have a lower initial cost compared to other roofing materials, the shorter lifespan means more frequent replacements, impacting long-term cost-effectiveness. Factors like maintenance costs and the potential for premature failure must be considered.

Cost and Lifespan Comparison

Source: pinimg.com

| Shingle Type | Initial Cost (per square) | Estimated Lifespan (years) | Approximate Cost per Year (per square) |

|---|---|---|---|

| 3-Tab | $80-$120 | 15-20 | $4-$8 |

| Architectural | $150-$250 | 25-30 | $5-$10 |

| Laminated | $200-$350 | 30-40 | $5-$12 |

Note: These are approximate figures and can vary significantly based on location, installer, and material choices. Consult local contractors for accurate pricing in your area.

Commonly Asked Questions: Asphalt Shingle Tiles

What is the average lifespan of asphalt shingles?

The lifespan of asphalt shingles varies depending on the quality, climate, and maintenance, typically ranging from 15 to 30 years.

Are asphalt shingles fire-resistant?

Asphalt shingles possess a degree of fire resistance, but their fire rating depends on the specific product and its classification. Check the manufacturer’s specifications for details.

How often should I inspect my asphalt shingle roof?

Annual inspections, particularly after severe weather, are recommended to identify and address potential problems early.

Can I repair damaged asphalt shingles myself?

Minor repairs, like replacing a few damaged shingles, are often manageable for DIYers. However, extensive damage necessitates professional assistance.

What are the signs of needing a new roof?

Signs include significant shingle damage, leaks, curling or blistering shingles, moss or algae growth, and sagging roof sections.