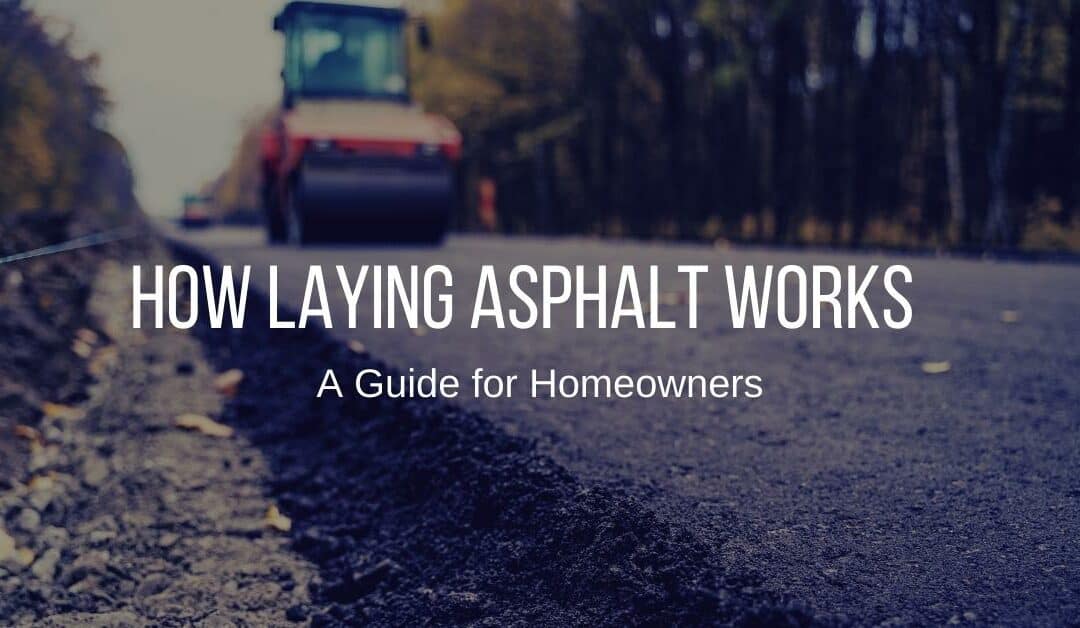

Installing Asphalt

Installing asphalt is a multifaceted process requiring careful planning and execution. From selecting the appropriate asphalt type—hot-mix, cold-mix, or specialized blends—to ensuring proper site preparation, each step plays a crucial role in the longevity and performance of the final surface. This guide delves into the intricacies of asphalt installation, providing a detailed overview of the process from initial site assessment to post-installation maintenance. We will explore the various techniques, equipment, and environmental considerations involved, aiming to equip you with the knowledge necessary for a successful project.

Understanding the nuances of asphalt installation, including the differences between various asphalt types, their respective applications, and the importance of proper compaction techniques, is vital for creating a durable and long-lasting surface. We will cover the critical aspects of site preparation, highlighting the significance of proper grading, compaction, and drainage. Furthermore, we will address environmental considerations and sustainable practices to ensure responsible and environmentally conscious asphalt installation.

Asphalt Installation: A Comprehensive Guide: Installing Asphalt

Asphalt pavement is a ubiquitous feature of modern infrastructure, providing durable and cost-effective surfaces for roads, parking lots, and driveways. Successful asphalt installation requires a meticulous approach, encompassing careful planning, precise execution, and diligent post-installation procedures. This guide provides a comprehensive overview of the entire process, from initial site preparation to final maintenance.

Types of Asphalt Installation, Installing asphalt

Source: theasphaltpro.com

Several types of asphalt exist, each suited to different applications and conditions. The primary distinction lies between hot-mix asphalt (HMA) and cold-mix asphalt (CMA). Other specialized types cater to specific needs, such as those containing recycled materials or designed for high-traffic areas.

Hot-mix asphalt requires mixing aggregates and bitumen at high temperatures (around 300°F) before placement. This creates a dense, durable surface ideal for high-traffic roads and highways. Cold-mix asphalt, conversely, uses lower temperatures and can be mixed and laid more quickly, making it suitable for smaller projects, patching, or temporary surfaces. Specialized asphalts incorporate additives for enhanced performance, like improved flexibility or resistance to cracking in colder climates. The longevity and cost-effectiveness vary considerably depending on the type selected and the specific project requirements.

| Type | Application | Cost | Longevity | Maintenance Requirements |

|---|---|---|---|---|

| Hot-Mix Asphalt (HMA) | Highways, major roads, parking lots | Higher initial cost | 15-20 years (or more with proper maintenance) | Regular crack sealing, pothole repair |

| Cold-Mix Asphalt (CMA) | Patching, temporary surfaces, low-traffic areas | Lower initial cost | 5-10 years | More frequent patching and maintenance |

Preparation Before Asphalt Installation

Source: manmadediy.com

Thorough site preparation is crucial for a long-lasting asphalt surface. This phase involves several key steps to ensure a stable and even base.

Grading involves leveling the ground to the specified grade and slope, removing any obstructions or debris, and compacting the subgrade to achieve the required density. Proper drainage is equally important; adequate slopes and drainage systems prevent water accumulation, which can lead to cracking and premature pavement failure. Potential issues, such as unstable soil or unsuitable subgrade materials, should be addressed proactively. For example, weak subgrade can be stabilized through techniques like adding lime or cement. A comprehensive checklist ensures all these steps are completed before asphalt laying commences.

- Clear the site of all debris and vegetation.

- Perform excavation to reach the required depth.

- Compact the subgrade to achieve optimal density.

- Install proper drainage systems (e.g., ditches, culverts).

- Verify the grade and slope meet specifications.

- Conduct a final inspection before asphalt placement.

Asphalt Installation Process

Source: amppaving.com

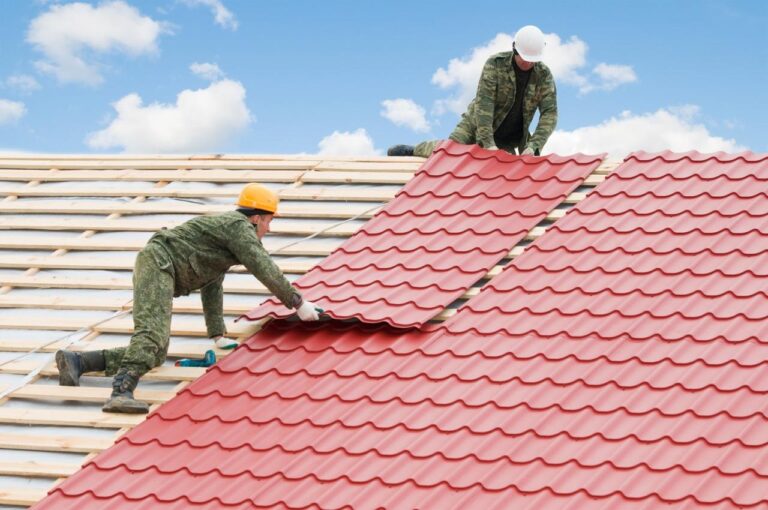

The asphalt installation process can be divided into distinct phases, each requiring specialized equipment and expertise.

- Base Preparation: This involves preparing the subgrade, adding base layers (e.g., gravel, aggregate), and compacting them to create a stable foundation.

- Asphalt Laying: Asphalt is delivered by trucks and spread evenly using paving machines. The thickness is carefully controlled to meet specifications.

- Compaction: Rollers, both static and vibratory, compact the asphalt to achieve optimal density and ensure a smooth, even surface. This removes air voids and increases strength and durability.

- Wear appropriate safety gear (hard hats, safety glasses, high-visibility clothing).

- Maintain a safe distance from moving equipment.

- Follow all traffic control measures.

- Regularly inspect equipment for proper functioning.

- Ensure proper ventilation in confined spaces.

Asphalt Compaction Techniques

Source: dreamstime.com

Achieving optimal density during compaction is paramount for asphalt’s long-term performance. Different compaction methods are employed, each with its advantages and limitations. Static rollers apply a consistent weight, while vibratory rollers use vibrations to increase compaction efficiency, especially in thicker layers. The number of roller passes, temperature of the asphalt, and density testing all play crucial roles in ensuring optimal compaction. Monitoring asphalt temperature is crucial as it significantly impacts compaction efficiency.

Optimal compaction is achieved through a combination of sufficient roller passes, appropriate roller type (static or vibratory, or a combination), and maintaining the asphalt within its optimal temperature range. Density testing, using methods like nuclear density gauges, verifies the achieved density against specifications.

Post-Installation Procedures

Source: ytimg.com

Post-installation procedures are critical for the longevity of the asphalt pavement. Proper curing allows the asphalt to solidify and reach its full strength. Protecting the newly laid asphalt from traffic and environmental factors until it cures sufficiently is crucial. Potential problems, such as cracking or rutting, can often be mitigated through proper post-installation care. A regular maintenance schedule helps prevent problems and extend the life of the pavement.

- Allow sufficient curing time (typically several days).

- Protect the surface from traffic until fully cured.

- Perform crack sealing as needed.

- Address any potholes or surface irregularities promptly.

- Regularly inspect the pavement for signs of deterioration.

Environmental Considerations

Asphalt installation has environmental implications, primarily related to material sourcing, energy consumption during production and installation, and potential air and water pollution. Minimizing these impacts requires careful consideration of materials and methods. The use of recycled materials in asphalt mixes reduces reliance on virgin resources and minimizes waste. Proper disposal of asphalt waste is also crucial to prevent environmental contamination.

- Use recycled materials in asphalt mixes.

- Optimize energy consumption during production and installation.

- Implement dust control measures to minimize air pollution.

- Properly manage and dispose of asphalt waste.

- Explore alternative paving materials with lower environmental impact.

Expert Answers

What is the typical lifespan of asphalt pavement?

The lifespan of asphalt pavement varies depending on factors like asphalt type, traffic volume, climate, and maintenance. It can range from 10 to 25 years or more.

How much does asphalt installation typically cost?

The cost of asphalt installation is highly variable and depends on factors such as project size, location, asphalt type, and site preparation requirements. It’s best to obtain quotes from multiple contractors.

Can I install asphalt myself?

While smaller projects might be manageable for DIY enthusiasts with the right equipment and knowledge, larger projects typically require professional contractors for optimal results and safety.

What are the common signs of asphalt damage that require repair?

Common signs include cracks, potholes, rutting, and surface deterioration. Addressing these issues promptly can prevent further damage and extend the lifespan of the pavement.

What type of equipment is needed for asphalt installation?

Necessary equipment includes rollers (static and vibratory), graders, pavers, and various hand tools. The specific equipment needs will vary depending on the project’s scale and complexity.